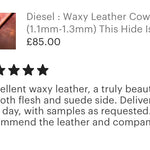

Featured products

Cheverette: Softy Veg-Tanned Leather

COLLECTION LIST

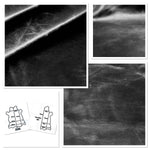

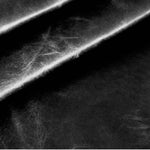

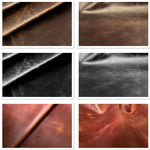

We have a vast amount of skins - Have a look! We probably have what you need for your next amazing project

ALL LEATHER HIDES

METALLIC LEATHER SKINS

KEEP ME UPDATED WITH OFFERS!

Subscribe to our newsletter and receive discounts, first look at new skins and bundle deals